COMPETENCIES

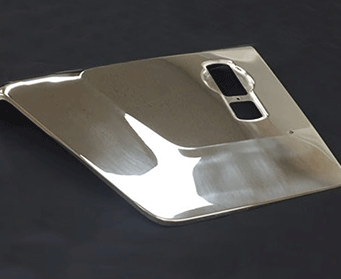

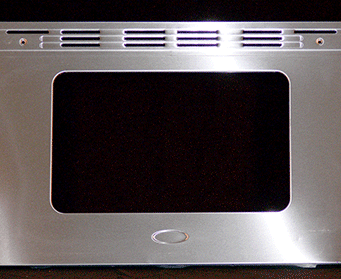

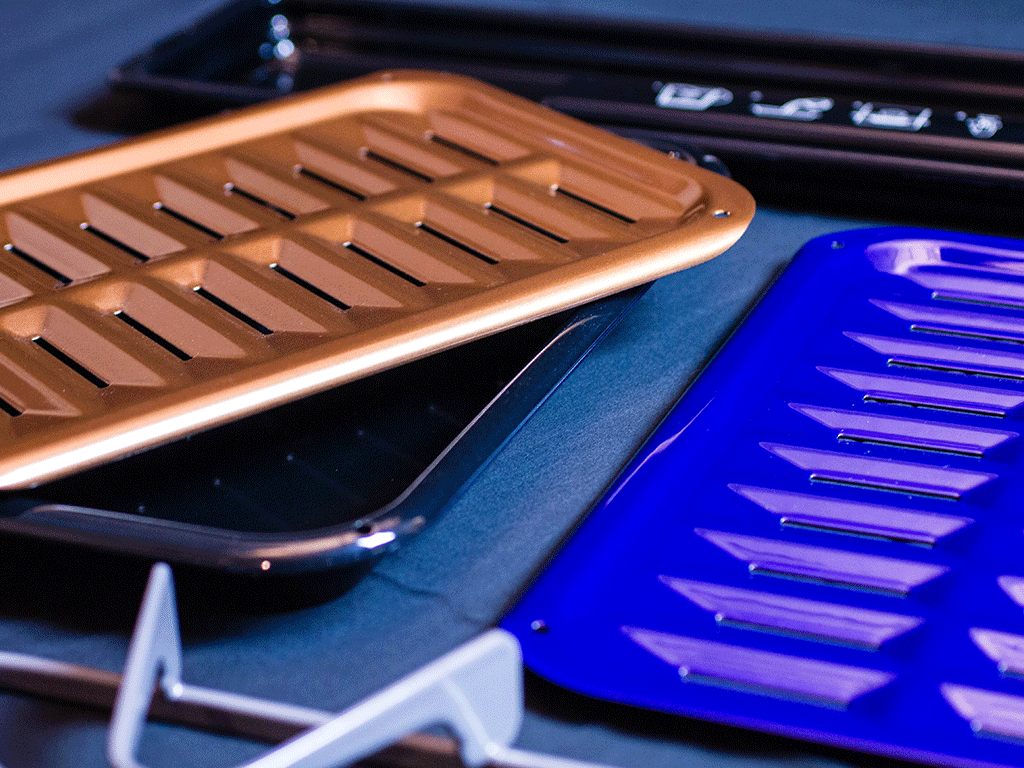

American Trim supplied components appear in a wide range of products from highly decorated control panels for the appliance industry, structural and cosmetic parts for the heavy-duty truck industry, and unique finishes for automotive trim.

TOOLING AND ENGINEERING

Expertise

American Trim has a long history in the forming of metal and composite substrates. In fact, many of our capabilities extend beyond 50 years and many of our employees have tenure in excess of 20 years. Our tooling and engineering resources know forming and know how to deliver the quality you need at the best possible value.

- Experience in multiple design programs

- Product and process development

- Die design: progressive, tandem, transfer

- Class A surface finish stamping dies

- Raw material selection and utilization

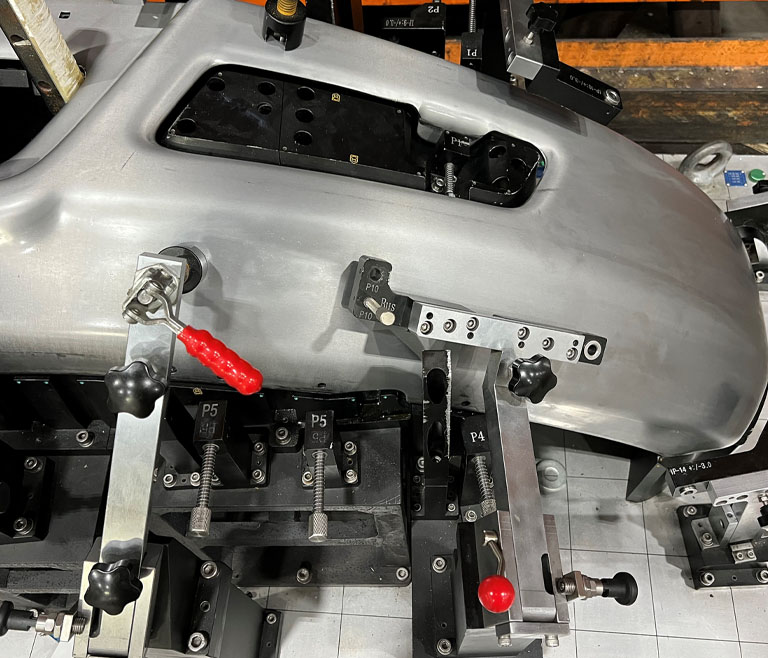

- Inspection gages and fixtures

- Project management for Tier 2 suppliers including plastic, painting, and chrome

Manufacturability

The Tool and Design group takes great care to allow the processing of very high-quality finishes. Precise fit and finish along with complete control of graphic registration are critical to our manufacturing processes.

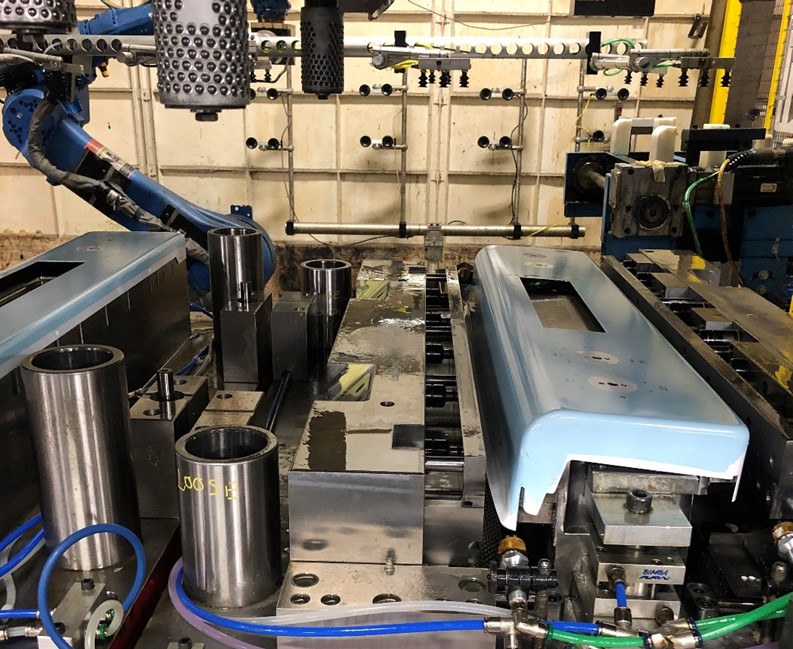

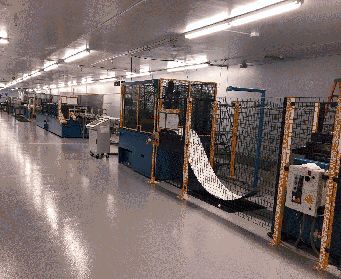

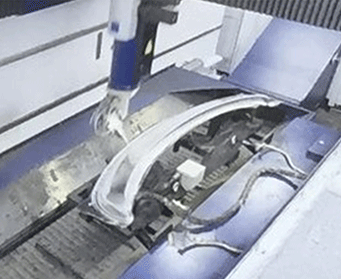

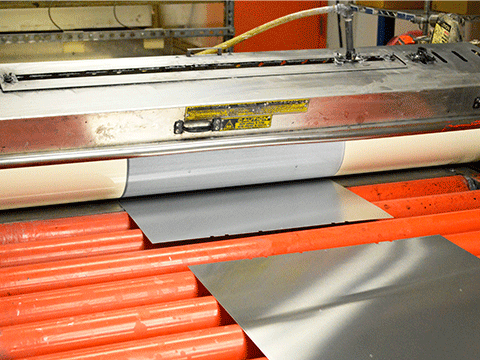

METAL STAMPING

American Trim provides structural components as well as decorated aesthetic items. We offer a broad spectrum of press sizes and auxiliary equipment to form complex shapes using materials from light aluminum to heavy gauge steel.

- Large bed, high tonnage stamping presses

- Coil or blank-fed presses

- Deep draw capabilities

- Stretch forming

- Progressive dies

- Transfer dies

- Class A surface finish

- Light to heavy gauge materials

- Structural and cosmetic components

- Pre-treated aluminum, steel, or stainless steel

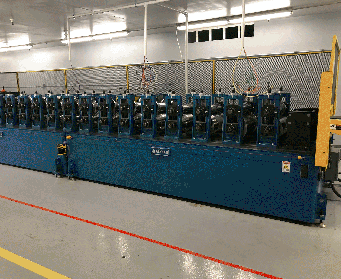

ROLL FORMING

American Trim has multiple roll forming lines with four to thirty stands capable of handling metal thicknesses from .005″ to .250″, and with spindle diameters from 1″ to 3″. Presses incorporated into the roll form lines can have in-line pre-pierce operations. We also offer lock seam, lance and tab, glue, and in-line welding.

FABRICATION

- Laser weld, cut, and etch

- 2D and 3D

- Stainless steel, aluminum, steel, and galvanized

- Shear

- Bend

- Mechanical and brake presses

- Plasma cutter

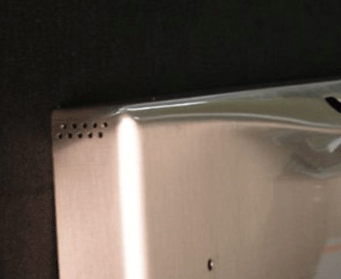

- Stainless steel polish

- Automated and manual

- Class A finish

- Brushed or bright mirror finish

- Stainless steel fabrication

- Fingerprint resistant coating

- High-quality welding

- Brushed finish

- Stainless steel bonding

- SS to SS bonding

- SS to plastic bonding

- Dual cure adhesive system to withstand severe stress/strain

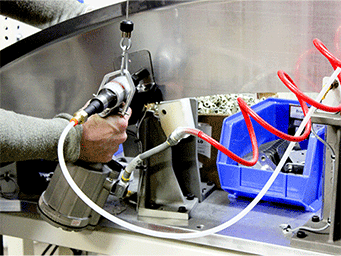

ASSEMBLIES AND INTEGRATION

Multiple joining and assembly operations provide completed assemblies for installation at OEMs.

Joining:

- Robotic welding systems for stainless steel, high-strength aluminum, and other substrates

- Welding

- Joining with adhesives, tapes, and specialty fasteners

Modular assembly with in-house manufactured and purchased components utilizing robotics systems:

- Laser cutting

- Glue joining

- Pick and place

- Injection molding

- Electronics integration

- Weldments

- Assembly

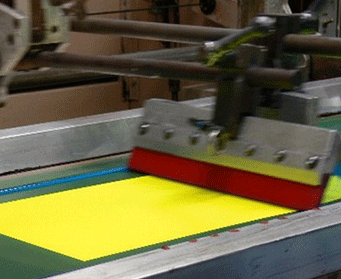

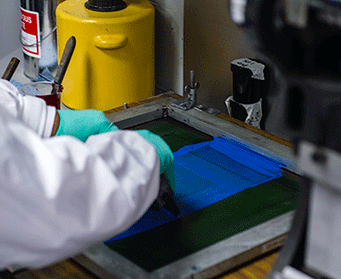

METAL DECORATING

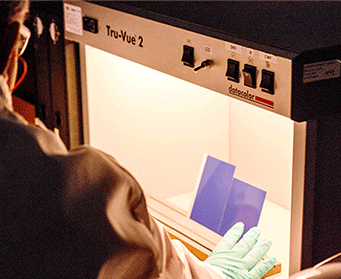

Metal decorating creates the ultimate branding opportunity for your products. Our in-house coating development provides custom color matching in batch sizes from 1 quart to 300 gallons. We validate these coatings and processes at scale in our fully equipped analytical lab and plant environments.

- Screen printing for precise images

- Fingerprint resistant coatings

- Conventional and UV curable base

- Selective finishes and textures

- Full face brush

- Selective brush

- Selective screening

- Temporary masking

- Embossing

American Trim offers many decorative and functional coating processes that provide

durability, reliability, and are cost-effective to improve your overall product.

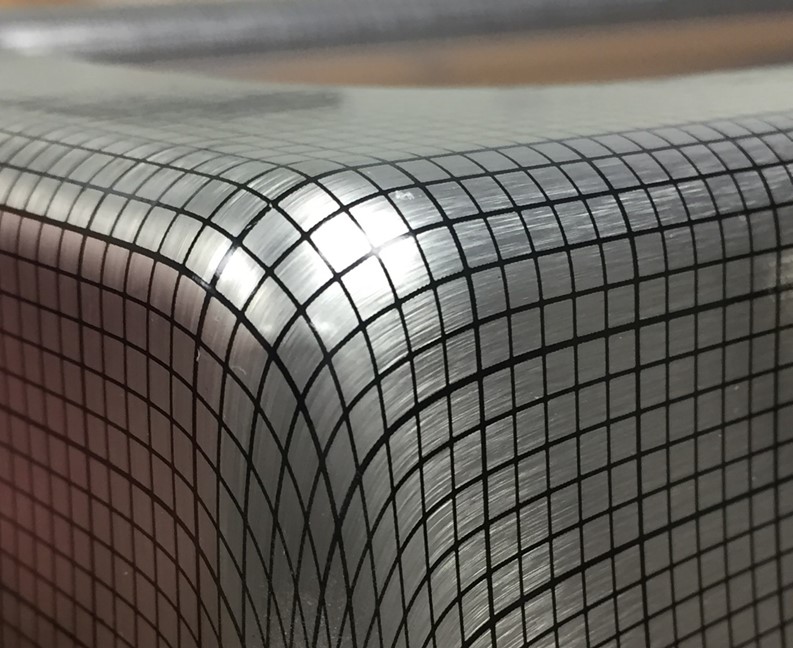

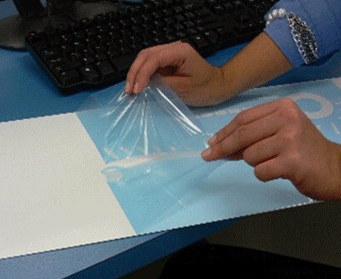

SELECTIVE PROTECTIVE FILM

Selective film is precisely aligned providing protection through forming to the end consumer.

- Precision selective film protection

- Replaces laminate film

- Specialty blends manufactured in a range of batch sizes

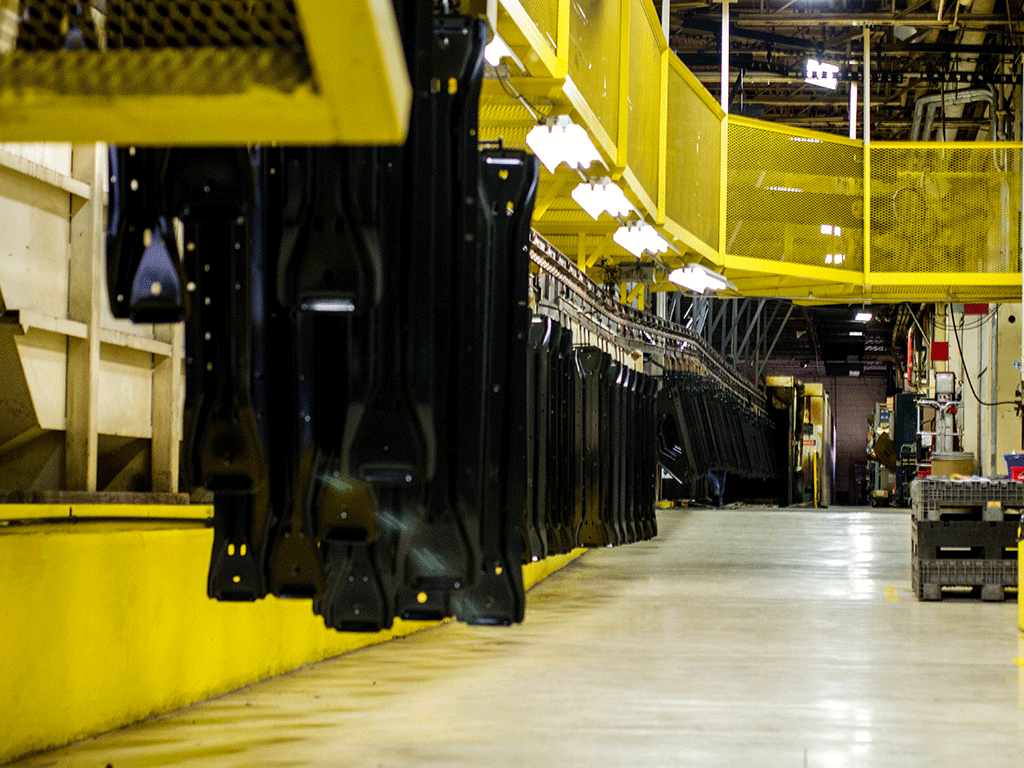

E-COAT/POWDER COAT

- Integrated line for efficient flow

- Corrosion resistance and UV protection

- Water-based, environmentally friendly process

- High material transfer efficiency

- Individual parts or assemblies

- Masking available

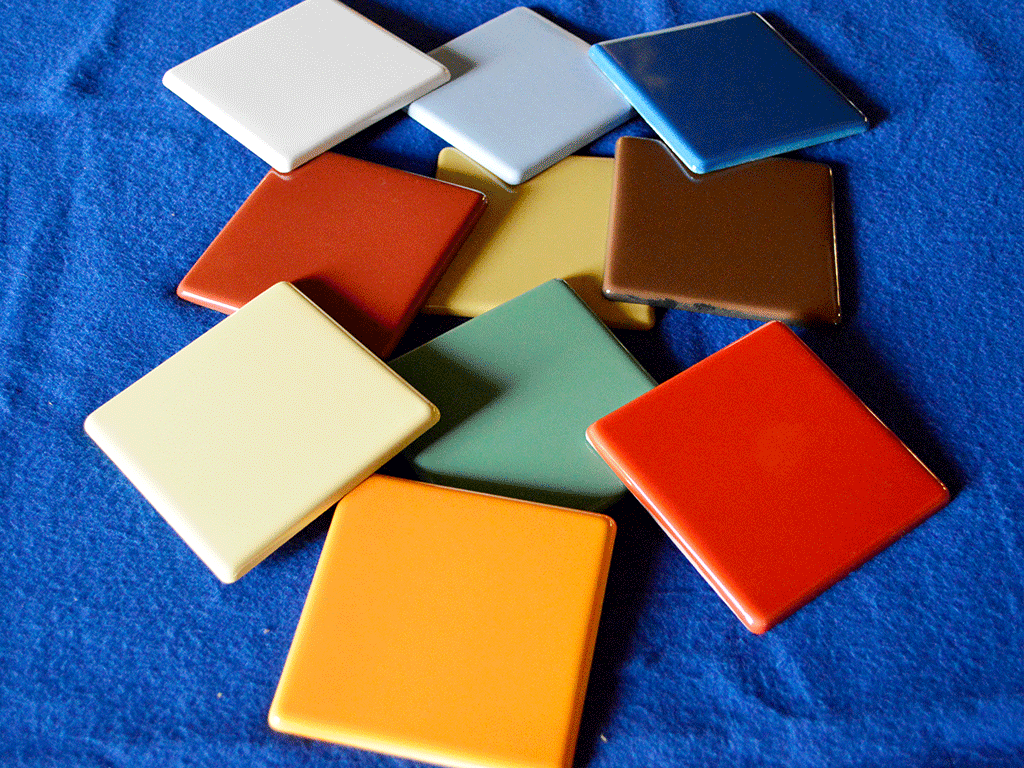

PORCELAIN ENAMEL

- Withstands extreme temperature changes

- High or low gloss

- Scratch and abrasion resistant

- Chemical and corrosion resistant

- Impact resistant

- Variety of colors

- Easy to clean and maintain

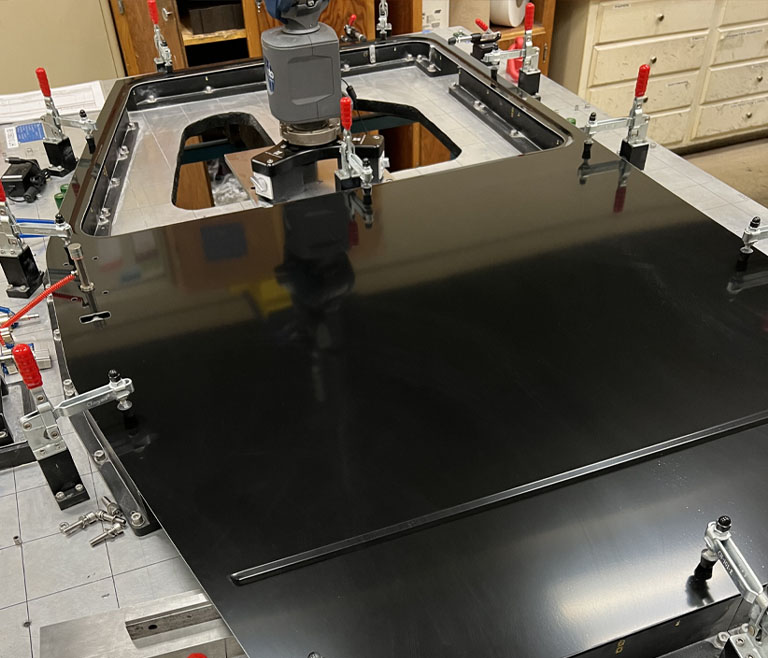

ROLL COATING

- Retains high-quality finish through forming operations

- No overspray reducing emissions

- Class A surface finish

- High- and low-volume runs

- Blanks up to 48” x 60” depending on material weight

- Pre-treated aluminum, steel, or stainless steel

- Finish options: semi-transparent, transparent, opaque, metal effects

COATING DEVELOPMENT & SUPPORT

- Quality control lab and analytical lab

- UV formulating and manufacturing

- Batch sizes from 1 quart to 300 gallons

- Color matching

- Art support

- In-house screen making